Circular connectors

Comprehensive Connectivity Solutions

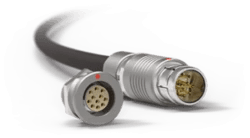

Fischer circular connectors cater to a wide range of applications, including low/high voltage, coaxial and triaxial connections, hybrid designs, fiber optics, push-pull mechanisms, and even fluid or gas transmission. With over 30,000 circular connector product references, Fischer ensures reliable power, signal, and data connectivity.

Engineered for Performance

Backed by more than 70 years of expertise, Fischer connector solutions excel in harsh environments, offering superior durability, sealing, hermeticity, miniaturization, high-density configurations, and flawless data transmission.

Customizable Options

Choose from an extensive selection of shell sizes, keying configurations, and pin layouts to meet your specific requirements.

Circular Connectors by Application

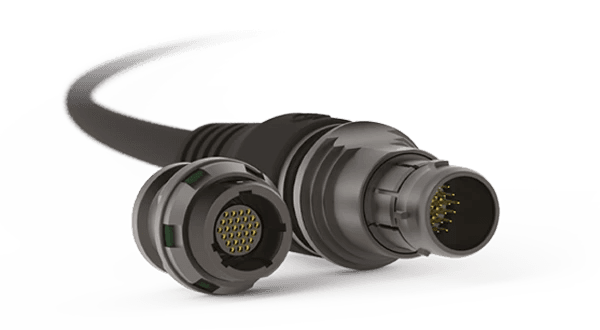

All Our Series Feature Rugged Connectors

Heavy-use or safety-critical applications are designed to withstand mechanical stress and environmental conditions without compromising power, signal, or data transmission.

Built to Endure Toughest Conditions

Our circular connectors, cables, and electronic solutions are built with robust materials and a rugged design:

Ruggedization Methods and Processes

Our ruggedization methods pertain to the entire designing, engineering, and manufacturing chain of our circular connectors, cable assemblies, and electronic solutions. This includes choosing high-quality materials for housing, coating, plating, insulating, and sealing, as well as overmolding or jacketing cables to protect the insulation and conductor core against environmental aggression and chemical deterioration.

Resistance of Our Materials

Check out which material is most suitable for your application.

Shell Material

| Material Name | Ideal For | Temperature | Main Attributes |

|---|---|---|---|

| Chromium-plated brass | Ruggedness | -100 to +200°C | Salt mist and mechanical resistance, cost efficiency, electrical conductivity |

| Aluminum | Lightweight | -100 to +200°C | Lightweight |

| Stainless steel | Cleaning / Radiation | -100 to +350°C | Corrosion resistance, surface cleanability, nuclear radiation and mechanical resistance |

| PEI | Sterilization | -65 to +200°C | Sterilization in autoclave, EtO, Cidex, gamma radiation, Steris®, Sterrad® |

| PBT | Insulation | -65 to +135°C | Electrical insulation, low temperature manipulation |

| ABS | Cost efficiency | -20 to +65°C | Disposable solutions, medical applications |

Contact Block Material

| Material Name | Ideal For | Temperature | Main Attributes |

|---|---|---|---|

| PEEK | High temperature | -65 to +250°C | High temperature, high chemical and high radiation resistance |

| LCP | High temperature | -65 to +200°C | High temperature and high chemical resistance |

| PBT | Cost efficiency | -65 to +135°C | High chemical resistance, cost efficiency |

| PTFE | Electrical insulation | -65 to +160°C | High dielectric strength, high chemical resistance |

| ABS | Cost efficiency | -20 to +65°C | Disposable solutions, good stability |

O-Ring & Sealing Material

| Material Name | Ideal For | Temperature | Main Attributes |

|---|---|---|---|

| FPM (Viton®) | Hermeticity | -20 to +200°C | Acids, weather, ozone, fuels, mineral and silicone oils, high vacuum, gamma rays |

| EPDM | Low temperature | -50 to +200°C | Alcohol, weather, hot water, vapour, detergents, gamma rays |

| NBR | Oil resistance | -30 to +110°C | Acids, mineral oils, petrol, weather, detergents |

| FVMQ | High temperature oil resistance | -55 to +200°C | Mineral oils, alcohol, weather, hot water, detergents |

| TPE | Soft accessories | -55 to +130°C | Very resistant, except to aromatic and chlorinated hydrocarbon |

| Silicone based resin | IP68 sealing | -55 to +200°C | Mineral oils, acids, alkalines, inorganic saline solutions |

| Epoxy based resin | Hermeticity | -65 to +150°C | High chemical and radiation resistance |

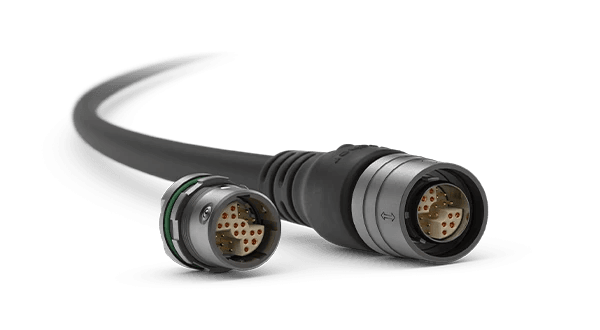

Our Series Overview

Five product lines with specific features and benefits for your application requirements and operating environments.

|

|

|

|

|

|

|---|---|---|---|---|---|

|

|

|

|

|

|

| Highly configurable, the Fischer Core Series offers a great variety of waterproof connectors. | Our ultra-rugged waterproof connectors are compatible with the latest military standards. | Our low profile, 360° mating Freedom connector is cleanable by hand in the water. | Combine water resistance with high-density miniaturization. | A rugged fiber-optic solution designed for outdoor applications. | |

| Number of contacts | 1 to 55 | 2 to 42 | 4 to 7 | 4 to 30 | 1 to 4 |

| Contact termination | Solder | Crimp | PCB | Solder | Crimp | PCB | Solder | PCB | Wires | ZIF | Solder | PCB | Optical | Solder (hybrid) |

| Locking system | Push-pull | Quick-release | Friction | Quick-release | Push-pull | Ratchet | Quick-release | Push-pull | Quick-release | Screw | Push-pull |

| Blind mating | ✔ | ✔ | ✔ | ✔ | ✔ |

| Mating cycles | up to 10,000 | up to 10,000 | up to 1,000 | up to 5,000 | up to 1,000 |

| Data transfer & power | ✔ | ✔ | ✔ | ✔ | ✔ |

| Contact type | Low voltage | High voltage | Coax | Triax | Hybrid | Low voltage | Low voltage | Low voltage | Low voltage | Fiber optic |

| Sealing level | IP30 to IP69 | Hermetic | IP68 to IP69 | Hermetic | IP67 to IP68 | IP68 | IP67 to IP68 |

| Receptacle sealed unmated | ✔ | ✔ | ✔ | ✔ | ✔ |

| Data protocol compliance | USB 3.2 | Ethernet | Single Pair Ethernet | Audio/UHD Video | USB 3.2 (MP LV or USB-C Interface) | Ethernet | Single Pair Ethernet | USB 2.0 | USB 3.2 | Ethernet | Single Pair Ethernet | Audio/UHD Video | – |

| Test voltage DC (kV) | up to 50 | up to 3.7 | up to 1.2 | up to 2.4 | up to 2.8 |

| Current rating (A) | up to 60 | up to 26 | up to 5 | up to 10 | up to 10 |

| Housing material | Brass | Stainless steel 316 L | Aluminum | PEI (405) | PBT (4032) | ABS | Aluminum | Brass | Metal | Plastic | Brass | Brass |

| AWG | 9 to 32 | 9 to 32 | 24 to 28 | 18 to 28 | 17 (hybrid) |

| Cable outer Ø (mm) | 1.5 to 22.7 | 1.9 to 18.8 | 5.5 | 3.0 to 8.7 | 2.9 to 9.4 |

| Plug size Ø (mm) | 9 to 34 | 12 to 29 | 20.4 to 25.4 | 9.9 to 14.9 | 13 to 24 |

Discover More About Our Rugged Circular Connectors

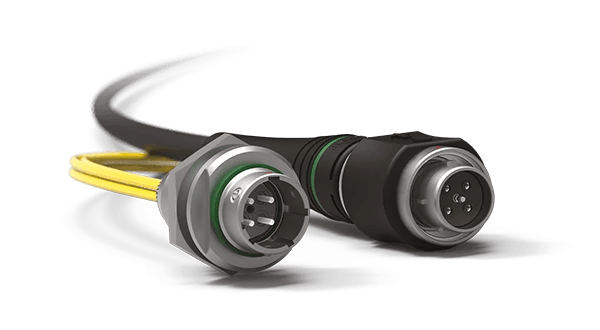

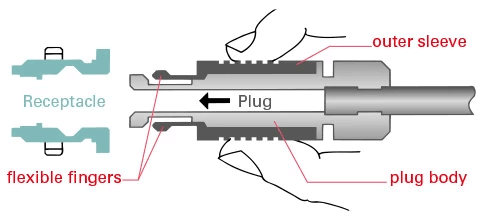

Our Original Push-Pull Locking System

Mating

MatingThe plug’s outer sleeve, with flexible fingers, slides forwards and backwards along the body.

When Connected

When ConnectedThe beveled edges are firmly captured by a locking groove located inside the receptacle.

Pulling the Cable

Pulling the CableThe beveled edges of the fingers are forced into the groove, securing the connection.

Unmating

UnmatingPulling on the outer sleeve of the plug unlocks the latching mechanism.

Other Locking Systems

Extreme Temperature Resistance

Our most rugged series offers standardized products that operate within the temperature range of -55 °C to +135 °C, tested in compliance with the Military Standard 810 Methods 501.6 and 502.6. With the right insulator and cable clam set, Fischer Core connectors can even withstand temperature ranges from -70 °C to +250 °C (and -100 °C upon request).

Vibration and Shock Resistance

Tested in compliance with MIL standard 202 Method 214 and Condition I, our connectivity solutions resist random vibration of up to 37.80 Grms for our most rugged series. Mounted onto vibration equipment, the locking and contact specifications of a circular connector pair are thoroughly verified.

Corrosion Resistance

Protection against corrosion mechanisms – pitting, intergranular or crevice – is achieved by choosing the right materials and type of coating. The most common materials and coatings used are:

Chemical Resistance

In hospital sterile environments, dentistry and laboratory settings, as well as in food and pharmaceutical processing, devices and equipment must be cleaned, disinfected and sterilized on a regular basis. Our products’ components – shells, contact blocks, O-rings and seals, cable jackets, etc. – are made of ultra-resistant materials to withstand the conditions incurred by sterilization methods with chemicals such as Steris LCS, Sterrad and EtO.

Sterilization Proof

If you’re in need of high-performance connectors that withstand most sterilization methods, consider the Fischer Core Series. These circular connectors are made with premium materials making them capable of withstanding temperatures ranging from -70 °C to +250 °C.

Radiation Resistance

Radiation resistance is required for long-lasting tasks in nuclear or contaminated environments such as handling heavy radioactive loads, performing inspections, and repairing equipment – sometimes performed remotely by robot workers due to inaccessibility or the danger of radiation exposure.

Proven and Tested

Off-the-shelf, customized or tailored to your needs, our high-performance solutions are designed to last. In order to reach the highest reliability and quality standards, our circular connectors go through a battery of mechanical and environmental tests, in compliance with industry and military standards such as IEC, EIA, MIL-STD-202 and MIL-STD-810.